From steel to fiberglass; Discover the best material for the future of the industry

From steel to fiberglass; Discover the best material for the future of the industry

Abstract: In this article, we provide a detailed comparison between steel, wood, Polymer, fiberglass and possibly other materials, by deeply examining the characteristics of each material, we analyze their advantages and disadvantages and finally, we prove that fiberglass is the best material. It is for the future industry in different fields.

1. Introduction

In the modern world, choosing the right material for any project has become an artistic technology. From huge architectural structures to precise medical devices, every human work is a symbol of the choice of material that not only shapes the physical characteristics of that project but also reflects the spirit of the times and the human search for excellence and sustainability. Meanwhile, steel, wood, polymer, fiberglass and other new materials each have a story in turn; A story of resistance, flexibility and harmony with the environment that every time promises a new season in industry and technology.

In this article, we are going to take a deep and detailed look at the world of materials. Our goal is to open a new window for you and provide an accurate and comprehensive picture of the capabilities, advantages and disadvantages of each of these materials. We want to accompany you on a knowledge-based journey so that, with a better understanding of the properties of each material, you will find out the reasons for the superiority of fiberglass, not as a claim, but as a fact based on a detailed comparison.

Let's remove the curtain of the mystery of materials together and step into a world full of possibilities and innovations that each of these materials brings. The article before you is not only a retelling of data and information, but a journey into the heart of technology and innovation, where fiberglass plays a pivotal role as a shining star.

2. Examination and comparison of materials

In the material review and comparison section, we provide an in-depth and technical analysis of each of the materials in question, a deeper understanding of different materials can lead to a more informed choice in different projects. Let's review the uses, advantages and disadvantages of each of the materials discussed:

1.2. فولاد (Steel):

- Physical and mechanical characteristics: Steel is an alloy consisting of iron (Fe) and carbon (C), which has high tensile strength and good toughness.

- Applications: Steel is a key material in the construction of load-bearing structures such as bridges, towers and high-rise buildings due to its high strength and ability to withstand heavy pressures. Also, it plays a very important role in the automotive industry and the manufacturing of cutting tools and industrial machinery.

- Advantages: Steel has very high strength, resistance to pressure and tension, and its weldability and malleability are unmatched in the industry.

- Disadvantages: The main problem with steel is rust, which can damage its structure over time. In addition, its relatively high weight can be a limitation in some projects.

2.2.چوب (Wood):

- Physical and mechanical characteristics: Wood is an organic material with a cellular structure that has good resistance to compressive forces.

- Applications: Wood has long been used in building, making furniture and art objects. This material has always been of interest due to its natural beauty and the warmth it gives to the space.

- Advantages: Wood is a sustainable and renewable material that gives natural warmth and special beauty to the space. Also, it has good flexibility and resistance to pressure.

- Disadvantages: The main disadvantages of wood include sensitivity to moisture, temperature changes and pest attack. In addition, it has little resistance to fire.

3.2.پلیمرها (Polymers):

- Physical and mechanical characteristics: Polymers are materials with long molecular chains that can have high flexibility and chemical resistance.

- Applications: Due to their high diversity, polymers are used in many fields including packaging, manufacturing of electronic devices, medical equipment and many others.

- Advantages: These materials have many advantages due to their light weight, flexibility and resistance to chemical factors and impact. Also, their malleability at low temperatures makes it possible to make products with complex designs.

- Disadvantages: The main problems with polymers include sensitivity to UV light and limitations in environmental degradability. Some polymers may have little heat resistance.

4.2.فایبرگلاس (Fiberglass):

- Physical and mechanical characteristics: Fiberglass is a composite consisting of glass fibers and polymer matrix, which has high strength.

- Applications: Due to its light weight and high strength, fiberglass is used in the aerospace, automotive, construction, boat and sports equipment industries.

- Advantages: This material has a very high resistance to corrosion and its light weight helps to improve efficiency and reduce energy consumption. In addition, its strength and durability against various environmental conditions is remarkable.

- Disadvantages: Although fiberglass has many advantages, it can be brittle against impact and may also be harder and more complex to form than other materials in some cases.

These detailed technical analyzes allow us to have a deeper understanding of each material and its potential compared to other options, and in this way we can make a logical and reasoned argument for the superiority of fiberglass.

Comparison table of advantages and disadvantages Materials

| Materials | Advantages | Disadvantages |

| Steel | High resistance to pressure and tension, weldability and malleability | Rust, relatively high weight |

| Wood | Sustainable and renewable, natural beauty, good pressure resistance | Sensitivity to moisture, temperature changes and pest attack, low resistance to fire |

| Polymers | Light weight, flexibility, resistance to chemical factors and impact, malleability at low temperatures | Sensitivity to UV light, limitations in environmental degradability, low heat resistance |

| Fiberglass | High resistance to corrosion, light weight, strength and durability against various environmental conditions | Fragility against impact, hardness and complexity in shaping in some cases |

3. Material analysis:

Steel:

Steel is known as one of the most widely used materials in the industry. The high strength of steel, especially against compression and tension, makes it an ideal option for building large and heavy structures such as bridges and high-rise buildings. However, rust can damage its structure over time and requires constant maintenance. The relatively high weight of steel can also create limitations in some projects.

Wood:

Wood, with its natural beauty and the warmth it gives to the space, is popular in the furniture and interior decoration industries. This material is environmentally stable and has good pressure resistance. However, sensitivity to moisture and pests, as well as low resistance to fire, limits its use.

Polymers:

Polymers are used in many fields due to their light weight, high flexibility, and resistance to chemical agents. The plasticity of polymers at low temperatures makes it possible to make products with complex designs. However, sensitivity to UV light and limitations in environmental degradability pose challenges in their use.

Fiberglass:

Fiberglass, due to its high resistance to corrosion and light weight, is a desirable choice, especially in the automotive and aerospace industries. The strength and durability of this material against different environmental conditions make it a suitable option for applications that require durability and high performance. However, its fragility against impact and complexity in shaping can create limitations in some cases.

4. Conclusion and emphasis on the superiority of fiberglass:

By carefully examining the characteristics, advantages and disadvantages of each material, we can conclude that fiberglass is superior in many areas. High corrosion resistance, light weight, and its strength and durability against various environmental conditions make it an ideal option for various applications. Especially in industries where there is a need to reduce weight and increase durability, fiberglass can play a key role.

Fiberglass's fragility against impact and complexity in shaping may present challenges, but with technological advances and the development of new manufacturing methods, these limitations can be minimized. Finally, the selection of fiberglass as a superior material is based not only on its technical and mechanical properties, but also on its potential to meet the changing needs of various industries and its impact on the future of technology and sustainable development.

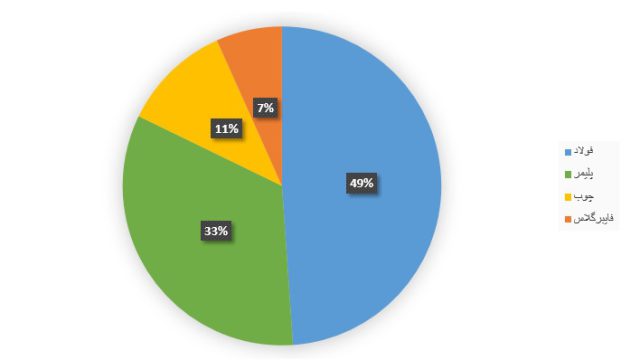

5.Distribution of material use in different industries

Providing accurate and universal percentages for the use of materials such as steel, wood, polymers, and fiberglass in various fields may be challenging due to the wide variety of applications, geographic variations, and technological developments. However, it is possible to provide a general and very approximate view of the distribution of the use of these materials in different sectors. It should be noted that these numbers are approximate and are more to give a general idea:

These percentages are estimated based on the general distribution of material use in different industries, and it should be noted that market changes, technological advances, and environmental policies can affect these figures.

The diagram above shows that the importance and value of fiberglass in the industry has not been well seen, but due to the speed of industrial developments in the world, it is expected that fiberglass will find its main place in the industrial future and the unique potential of this material in various industries with be used creatively.

A call to action

آیا به دنبال راهکارهای نوآورانه و با دوام در صنعت خود هستید؟ «آرتاکامپوزیت» با ارائه طیف گستردهای از محصولات و خدمات مبتنی بر فایبرگلاس، همراه قدرتمندی برای رسیدن به اهداف شماست.

از محصولات ساخته شده توسط ما در این وب سایت دیدن کنید و با متخصصان ما تماس بگیرید تا بدانید چگونه میتوانیم به شما در تحقق پروژههای پیشرو کمک کنیم.

با آرتاکامپوزیت (Artacomposite)، نوآوری و دوام را به پروژههای خود بیاورید. همین حالا اقدام کنید!

برای کسب اطلاعات بیشتر میتوانید با ما تماس بگیرید.

1 Comment

سلام خیلی عالی بود ممنونم