Fiberglass covers: a new solution to protect machinery

Design and manufacture of machine covers

(فرایند طراحی و ساخت کاور فایبرگلاس ماشین آلات)

Abstract: In this article, we have taken a comprehensive look at the process of designing and manufacturing fiberglass covers for machinery. We examine how this innovative technology increases efficiency, reduces costs and improves safety. This article shows how fiberglass covers can become a key element in the machinery industry.

Introduction: In today's advanced world, the machinery industry is always looking for innovative and sustainable solutions to improve efficiency and increase the life of equipment. Meanwhile, the use of fiberglass covers in industrial machinery is not only a step towards innovation, but also a leap towards durability and safety. This article examines how fiberglass covers are designed and manufactured and shows how this technology can provide significant benefits. We will provide an in-depth analysis of the processes used in the production of fiberglass covers and show how this innovative approach can help reduce maintenance costs, increase efficiency, and improve machinery safety. Also, by introducing case studies and real examples, we will investigate the impact of this technology on the market and different approaches of different industries. Finally, this article serves not only as a source of information for engineers and machinery manufacturers, but also as a valuable guide for those looking for innovative and sustainable solutions in the industry.

کاور فایبرگلاس ماشین آلات

Key benefits:

The use of protective covers, especially covers made of materials such as fiberglass, has several important advantages for devices and manufacturers:

1. Increasing durability and reducing maintenance costs: Protective covers make devices more resistant to external factors such as dust, moisture, corrosion and temperature changes. This helps to increase the lifespan of the devices and reduce maintenance costs.

2. Improved safety: Protective covers can help reduce the risk of injury to workers when working with devices. Also, in cases such as fiberglass covers that are thermal and electrical insulation, the safety of devices against fire and electric shocks increases.

3. Reduced manufacturing costs in the long run: While the initial investment to purchase or manufacture protective covers may be high, in the long run, the savings in maintenance and repair costs will reduce the overall cost. This issue is more important especially in industrial environments with harsh conditions where the risk of device failure and wear is greater.

4. Increase efficiency: Protective covers can help improve the efficiency of devices. For example, in environments with high pollution, covers prevent waste particles from entering the device and causing problems.

5. Market attractiveness: Using innovative protective covers can increase the attractiveness of products in the market. Products that come with added features such as higher safety and longer durability can attract a wider target market.

Finally, while the initial cost of providing or manufacturing protective covers may make some manufacturers hesitate, the long-term benefits of this investment, including reduced running costs, increased safety, and improved efficiency, often provide a significant financial benefit for them. This can lead to an increase in profitability and competitive position of the company in the market.

کاور فایبرگلاس ماشین آلات

The process of making machine covers

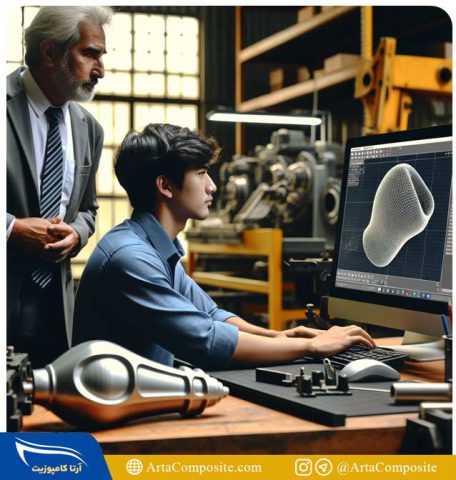

1. Basic design

- Check the needs and dimensions: Start the process by carefully checking the needs of the machines and determining the dimensions and shape required for the covers. This step includes accurate measurements and considering the necessary spaces for access and maintenance.

- 3D model design: Using CAD software, a 3D model of the desired cover is designed. This step helps to check the ergonomics and effectiveness of the design.

2. Selection of materials

– Selection of fiberglass: Choosing the right type of fiberglass based on the required characteristics such as strength, weight and heat resistance.

– Resins and other materials: Determine the type of resin and hardeners to create a strong and resistant composite.

3. Form making:

– Mold production: Based on the CAD design, molds are made from materials such as wood, plastic or metal. The molds must be designed exactly according to the dimensions and shapes of the model.

– Mold surface preparation: Molds are prepared with release agents such as wax or special coatings to prevent fiberglass from sticking to the mold.

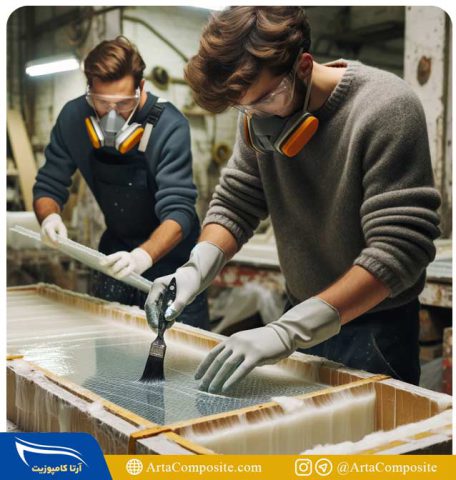

4. Fiberglass layering

- Cutting and preparation of fibers: Cutting fiberglass fibers into the shapes and sizes needed to be placed on the mold.

– Layering: Precise arrangement of fiberglass layers on the mold. This step may be done manually or using special machinery.

5. Resin casting and compression:

– Applying resin: Spreading the resin evenly on the fiberglass layers. The resin penetrates the fibers and creates a strong structure after hardening.

– Compression and heating: Using pressure and sometimes heat to ensure complete penetration of the resin between the layers of fiberglass and create a unified structure.

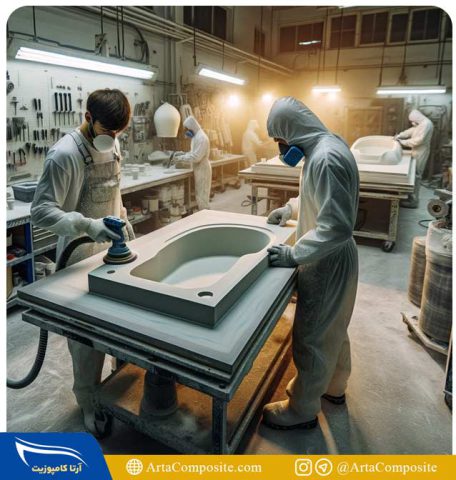

6. Payment and completion

– Removal from the mold: After the resin has completely hardened, the fiberglass cover is removed from the mold. This step requires high precision to avoid damage to the part.

– Sanding and polishing: Removing roughness and creating a smooth and uniform surface through sanding. After that, more polishing may be required to achieve the final appearance of the product.

7. Painting and final protection:

– Application of paint and protective coatings: To increase durability and resistance to external factors, fiberglass covers can be painted. Also, applying protective coatings such as anti-UV or anti-corrosion to increase the useful life of the cover.

– Final review and quality control: Perform detailed reviews to ensure quality and performance standards are met.

8. Installation and testing:

– Preparation for installation: Covers are prepared for installation, which may include the addition of additional components such as sealants, fasteners or special fittings.

– Installation on machinery: Fiberglass covers are installed on machinery, which can involve fine adjustments to ensure proper fit and optimal performance.

کاور فایبرگلاس ماشین آلات

Challenges and solutions of using fiberglass covers

Solution: Mechanical strengthening; Using reinforcements such as carbon fibers or nanoscale materials to improve the mechanical resistance of fiberglass against heavy loads and stresses.

Solution: Protective covers; Applying protective coatings such as anti-UV or chemical-resistant coatings for better protection of fiberglass in certain environmental conditions.

Solution: Optimizing the production process; Using innovative and efficient production methods to reduce costs and increase production speed, such as automation or additive manufacturing methods

Solution: Modular and flexible design; Designing modular and adjustable fiberglass covers to increase flexibility in installation and use in various applications.

Solution: sustainable solutions for recycling; Developing sustainable recycling and disposal methods for fiberglass, such as chemical recycling or reuse of fibers and resins in new products.

کاور فایبرگلاس ماشین آلات

Conclusion and call to action

At the end of this article, we gave a detailed and comprehensive explanation of the benefits and applications of fiberglass protective covers in the machinery industry. It was found that the use of these materials not only helps to increase the durability and efficiency of the devices, but also leads to the reduction of maintenance and repair costs and improvement of safety.

Now, it's time for manufacturers to take a more serious look at this innovative opportunity. Considering the many advantages of fiberglass covers, companies can use this technology to improve their products, improve competitiveness in the market and respond to the needs of customers in the modern world. Also, due to the increasing focus on sustainability and environmental responsibilities, the use of fiberglass covers can be recognized as a positive step towards reducing environmental effects and improving ecological standards.

Therefore, we invite manufacturers and industry managers to assess their current and future needs and explore how to integrate fiberglass covers into their manufacturing strategies. By investing in this technology, you not only help increase the quality and safety of your products, but also show society that you are committed to progress and innovation in order to protect the environment and improve working conditions.

You have this opportunity to advance and transform your industry in your hands. Now is the time to take action and take advantage of the countless benefits that fiberglass covers offer.

کاور فایبرگلاس ماشین آلات

Frequently asked questions about this industry

Following are the common questions that may be asked for different groups and I will provide answers for them:

کاور فایبرگلاس ماشین آلات

Contact information and links:

To learn more about fiberglass covers and how they can be integrated into the machinery industry, you can contact us Call .

Useful links:

– Products: To view our products and learn more about fiberglass covers, visit the [Products] section of the website.

- Articles and Blog: Visit the [Blog] section of the website to read specialized articles and the latest industry news.