health and safety challenges in the fiberglass industry; Solutions for a safer work environment

Safety and health recommendations in the fiberglass industry

1- Respiratory hazards and respiratory protection:

The first part of health and safety challenges at Fiberglass industry is concerned with "respiratory hazards and respiratory protection". This section includes two main components: identifying respiratory hazards and selecting appropriate respiratory protective equipment.

Identification of respiratory hazards:

Fiberglass, which is from Fiber is a finely formed glass that can introduce fine particles into the air during cutting, sanding, or other manufacturing processes. These particles can enter workers' respiratory tracts and cause irritation or more serious injuries.

Failure to comply with safety regulations causes serious and sometimes irreparable injuries to the workers of this industry, including:

-Throat and Lung Irritation: Inhalation of fiberglass particles can cause throat irritation, coughing and sometimes wheezing.

-Dermatitis and respiratory diseases: In long-term cases, continuous contact with fiberglass fibers can lead to dermatitis and respiratory diseases.

Respiratory protection:

To protect workers from these hazards, the use of appropriate respiratory protective equipment is essential. These equipment should be selected in such a way that they can prevent fiberglass particles from entering the respiratory tract.

Among the respiratory protection equipment are:

-Respiratory masks with filters: These masks can separate small particles from the air and prevent them from entering the respiratory tract.

- Full protective breathing systems: In environments with high concentrations of particles, the use of breathing systems that cover the entire face or head is recommended.

Therefore, to reduce respiratory hazards in the fiberglass industry, accurate identification of hazards and appropriate selection of respiratory protective equipment are critical. Also, training workers Knowledge of the proper use of this equipment and the dangers associated with fiberglass is essential to creating a safe and healthy work environment.

2- Skin contact and personal protection in the fiberglass industry

Skin contact with fiberglass or chemicals used in the industry can lead to skin reactions and other health problems. In the following, different aspects of this issue are explained.

Risks due to skin contact:

Fiberglass fibers can cause skin irritation and lead to redness, itching, and in some cases, dermatitis (skin inflammation), and some people may have allergic reactions to the chemicals used in Fiberglass production show.

Protective measures

Wearing full protective clothing that covers the skin and prevents direct contact with fibers, as well as using appropriate gloves that prevent direct contact of hands with fibers and chemicals can have a significant effect on protecting the skin of the hands. It should be noted that the use of safety glasses is also very important to prevent particles from entering the eyes. Finally, we must pay attention to the careful washing of the skin after contact with fiberglass and the use of skin protection creams can play an important role as a deterrent.

Risks and diseases caused by not following safety recommendations:

If safety recommendations are not followed, workers may face the following risks and diseases:

1. Dermatitis and skin inflammation: Continuous contact with fiberglass can lead to occupational dermatitis, a type of skin inflammation caused by contact with irritants.

2. Skin infections: Scratches caused by fibers may be entrance doors for skin infections.

3. Severe allergic reactions: In some cases, contact with certain chemicals can lead to severe allergic reactions.

4. Respiratory problems: Although this case is mostly related to breathing, suspended particles can also enter the body through the skin and aggravate respiratory problems.

3- 3- Management of chemicals and related risks

In the fiberglass industry, the management of chemicals and related risks is one of the most fundamental aspects of occupational health and safety. This industry uses various chemicals such as Uses resins, hardeners and catalysts, each of which has its own risks. For example, resins used in the manufacture of fiberglass can release vapors that pose a health risk if inhaled or in contact with the skin. Also, the hardeners used to harden the resins sometimes contain toxic chemicals that can pose serious health risks.

To deal with these risks, it is necessary that fiberglass production workshops are equipped with proper ventilation systems to remove harmful vapors from the work space. In addition, workers should receive adequate training on how to properly use these materials and the necessary precautions. The use of personal protective equipment such as gloves, protective glasses and special masks is also necessary to avoid direct contact with these substances.

In addition, proper management of chemicals includes safe storage of these materials, accurate labeling of containers containing chemicals, and having documented plans for dealing with spills and emergencies. These measures not only protect workers from existing hazards, but also help maintain a safe and healthy work environment. Finally, strict adherence to local and international laws and regulations related to the use and disposal of these chemicals is critical to ensuring safety in this industry.

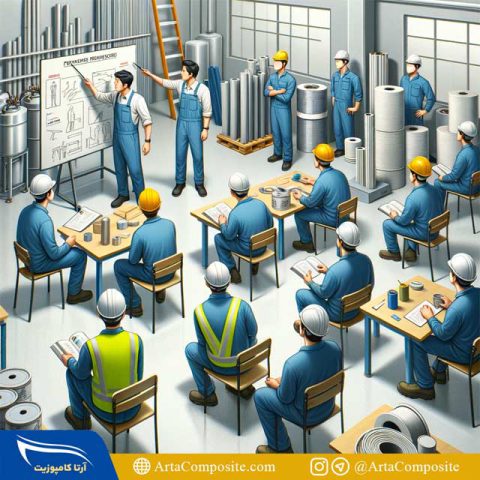

4- 4- Education and awareness of workers

Training and awareness of workers is one of the main pillars of safety and health in the fiberglass industry. These trainings should help workers to become familiar with the dangers in the work environment, learn how to use safety equipment correctly, and be aware of safe work methods. Training should include information on respiratory hazards, personal protection, safe use and disposal of chemicals, and emergency procedures.

Different methods can be used to carry out these trainings. Face-to-face classes that use visual presentations and hands-on demos can be very effective. These classes provide an opportunity for questions and answers and direct interaction between the trainer and the workers. Also, the use of educational videos that show the real conditions of working with fiberglass can help in better understanding the concepts.

In addition, holding hands-on workshops where workers can work directly with materials and equipment helps them put their knowledge into practice. Also, providing manuals and training brochures that contain important information and safety instructions can be used as reference sources for workers.

Finally, it is also important to conduct regular safety training review sessions and updates to ensure that workers are always aware of the latest safety standards and practices. These trainings not only help to maintain the health and safety of workers, but also lead to increased productivity and quality of work.

5- 5- Ergonomics and prevention of movement injuries

Ergonomics in the workplace examines and improves the interaction between workers and their work environment, especially in the fiberglass industry where workers may be exposed to various movement hazards. These hazards can include injuries from repetitive tasks, lifting heavy objects, or working in poor postures. Ergonomics seeks to create a work environment that is associated with minimal risk to the health and safety of workers.

To prevent movement injuries, the first step is to identify activities that may pose a risk. This includes carefully evaluating work processes and identifying situations where workers are required to perform repetitive motions, heavy lifting, or work in awkward positions. After identifying these risks, measures should be taken to reduce or eliminate them.

One of the effective methods in this field is the use of auxiliary equipment for lifting and moving heavy objects. For example, the use of cranes, trolleys, and other assistive devices can greatly reduce the pressure on workers. Also, it is important to design the work environment in such a way as to prevent inappropriate physical positions. For example, the height of work tables should be adjusted so that workers do not need to bend or stretch their bodies.

In addition, training workers on proper lifting and moving techniques can be helpful in preventing movement injuries. Workers should be trained how to lift heavy objects using leg and back muscles instead of back and shoulders.

Finally, providing opportunities for rest and variety in daily activities can prevent

Help from fatigue and injuries caused by repetitive work. This includes taking regular rest periods and changing work tasks to reduce stress on certain muscle groups.

In summary, ergonomics in the fiberglass industry plays a key role in maintaining the health and safety of workers, and motion injuries can be minimized by adopting different approaches.

6- 6- Waste management and disposal of pollutants

Waste management and disposal of pollutants in the fiberglass industry is one of the important issues that requires attention and careful planning. This industry can generate a variety of wastes, including fiberglass scraps, chemicals used in the manufacturing process, and other general wastes. These wastes and pollutants can have negative effects on the environment and human health, so their proper management is of great importance.

First, waste should be separated from the production stage. This means separating recyclable waste from hazardous and non-recyclable waste. For example, fiberglass scraps may be recyclable, while some chemicals must be disposed of as hazardous waste.

Next, safe and effective methods of disposal of waste and pollutants must be considered. For hazardous waste, such as chemical residues, safe disposal methods must be used in accordance with environmental regulations. This may include transport to a specialist facility for safe disposal or recycling.

For non-hazardous and recyclable waste, such as fiberglass scraps, effective recycling solutions must be adopted. This can help reduce the amount of waste produced and reuse resources.

In addition, planning to prevent contamination at the source is also important. This can include improving production processes to reduce waste generation, using less polluting raw materials, and adopting environmentally friendly technologies.

Finally, educating and informing employees about the importance of waste management and disposal is very important. Employees should be trained on the correct methods of waste collection, disposal and recycling and encouraged to follow these methods in the workplace. This not only helps to preserve the environment, but also leads to the creation of a responsible and sustainable work environment.

7- Checking and monitoring the work environment

Examining and monitoring the work environment in order to ensure compliance with safety and health in the fiberglass industry is of great importance. This process involves regularly reviewing the work environment, equipment and work methods to ensure that everything meets health and safety standards. These reviews can include checking personal protective equipment, ventilation systems, and the condition of tools and equipment being used. Also, it is important to check the conditions of the working environment such as lighting, sufficient space, and ergonomics of the workplace.

8- 8- Safety rules and regulations

Safety rules and regulations play an important role in maintaining the health and safety of workers. These laws can include national and international guidelines that determine how hazardous materials should be stored and disposed of, what type of safety equipment should be used, and how the work environment should be designed to prevent occupational accidents and illnesses. Compliance with these rules and regulations is not only important to avoid fines and prosecution, but also vital to maintaining a safe and healthy work environment for workers.

Translator and compiler: Mohammad Hassan Jafari